Rosalie

Scatole segrete- Rosalia

Scatole segrete- Rosalia

Struttura in multistrato di betulla rivestita in acero. Coperchio in acero massello e pomolo in ebano. Coloritura all'anilina rossa, finitura a cera.

Rosso

25.00

18.00

25.00

1.70

Scatola preziosa portagioie in legno, spedita in un cofanetto protettivo in legno multistrato, certificato di garanzia

Ettore Sotsass

«I wanted to design boxes to open, taking care to lift the lid slowly with two hands, as if the box could feel that I am kind to it and that I don't want to mistreat it in the slightest. Boxes made with precious woods where you can put even slightly secret things: a special brush, some special paper notebooks or more simply something that I would like to remain secret. Maybe notes from lovers."

Ettore Sottsass

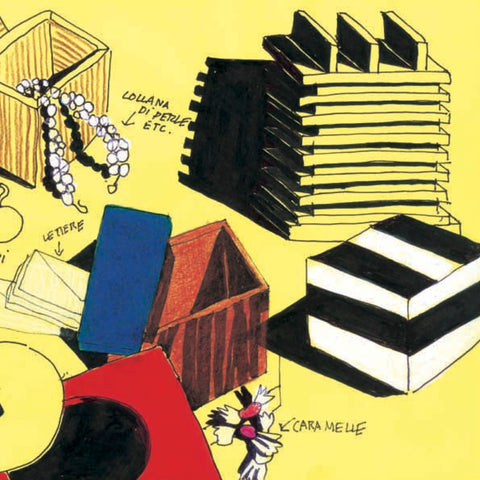

Ettore Sottsass designed Scatole Segrete for Numa, in plywood: five small architectures that express a very personal vision of the value of things: that symbolic value that certain objects full of meaning can take on when we use them for a very specific reason.

Rosalia , Agnese , Teresa , Zita and Agata are the names of the five wooden boxes offered in 99 numbered copies. Five small architectures that express a very personal vision of the value of things: that symbolic value that certain objects full of meaning can take on when we use them for a very specific reason. Five extraordinary interpretations by Ettore Sottsass of a traditional material such as wood, in the highly iconographic language that distinguishes this great designer.

Material:

- Local maple Europa worked in solid wood

- Proven ebony Indonesia worked in solid wood

- Birch native Russia. Birch plywood composed of 7 layers of 20/10mm with crossed fiber to make the wood stable.

Processing steps:

- The processing begins with a careful choice of wood to obtain a homogeneous effect of the color and pattern of the fibers.

- The birch plywood panel is veneered with a 20/10 mm layer of maple. on both faces.

- We proceed to cut the parts that make up the box.

- The parts are assembled by gluing and interlocking them; the horizontal joints are machined and joined by tapping; the vertical joints are made with internal wooden cores.

- The lid of the box is constructed by hand turning the solid maple.

- The knob is made by turning the solid ebony by hand, after carefully choosing the trunk. Ebony trunks are small in size and full of defects. There is a waste of approximately 70% to obtain blocks of solid wood suitable for processing. The knobs and the maple top of the lid are left to rest for several months to allow further stabilization of the wood

- After adequate time we proceed by working the surfaces of the box by hand with sepia paper and rounding the edges.

- The body of the box is painted with red aniline pigments.

- We proceed with a first coat of "primer" to close the pores of the wood.

- The surfaces are smoothed again by hand with increasingly finer sepia papers.

- We proceed with stamping.

- Another coat of paint is given, with a brush, to make the surface "silky".

- After adequate drying, a layer of natural beeswax is applied by hand.

- The knob is fixed to the lid of the box using a hidden, interlocking wooden cylindrical pin.

NB. The processing of ebony parts requires great care, as ebony releases a black powder when raw which penetrates the fiber of the other woods, soiling them irreparably. Ebony must therefore be worked alone and separated from other woods.

-